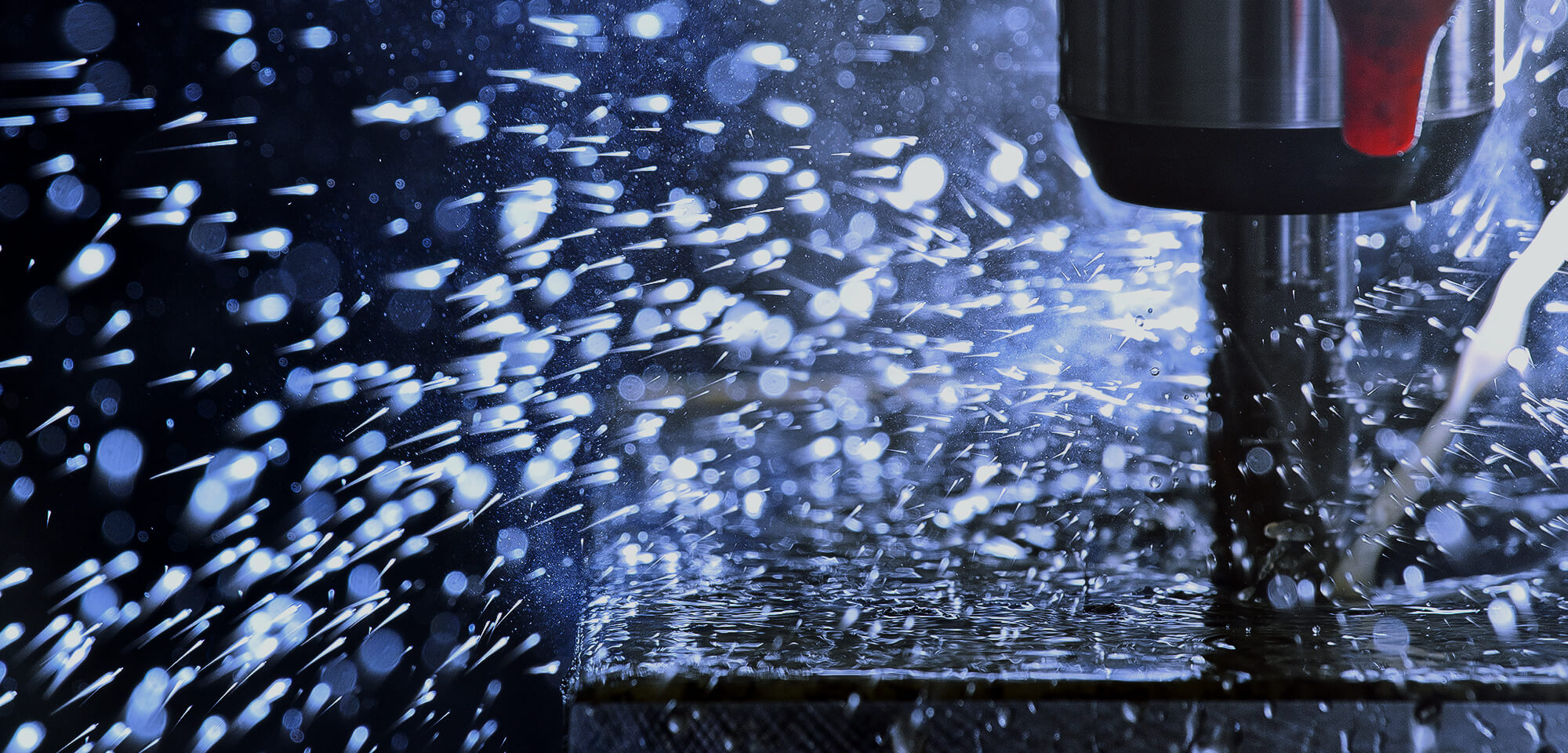

CNC Machining Capabilities

HyPro’s core strength lies in precision CNC machining, with more than 220 active machining centers across multiple U.S. plants. Our broad range of equipment and deep process control allows us to support a wide variety of metals, geometries and tolerances.

Our nationwide manufacturing footprint includes specialized facilities:

Every HyPro facility maintains ISO 9001:2015 registration. Our quality systems include:

Whether you're looking for a reliable partner for complex castings or a fully integrated contract manufacturer, HyPro delivers unmatched process depth and manufacturing expertise. Contact our team today to learn how we can support your next machining, assembly or sourcing project.