CNC Machining

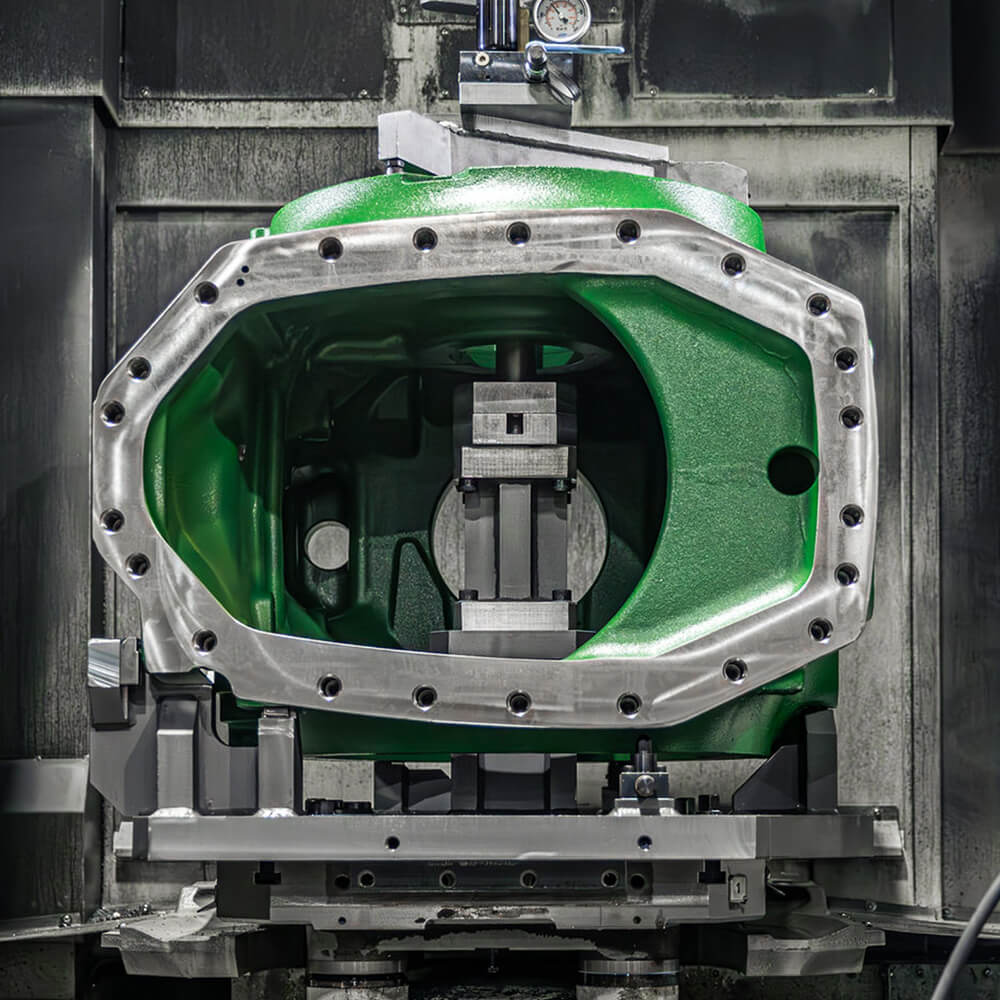

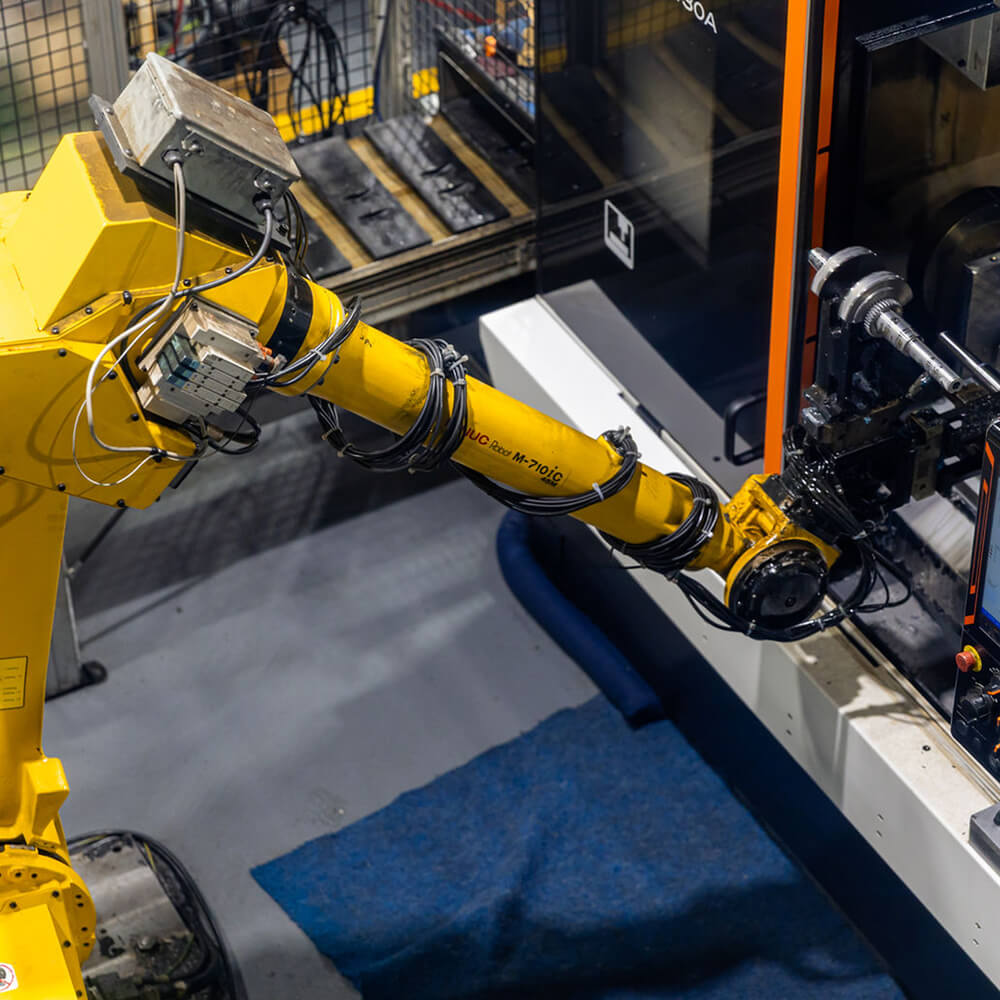

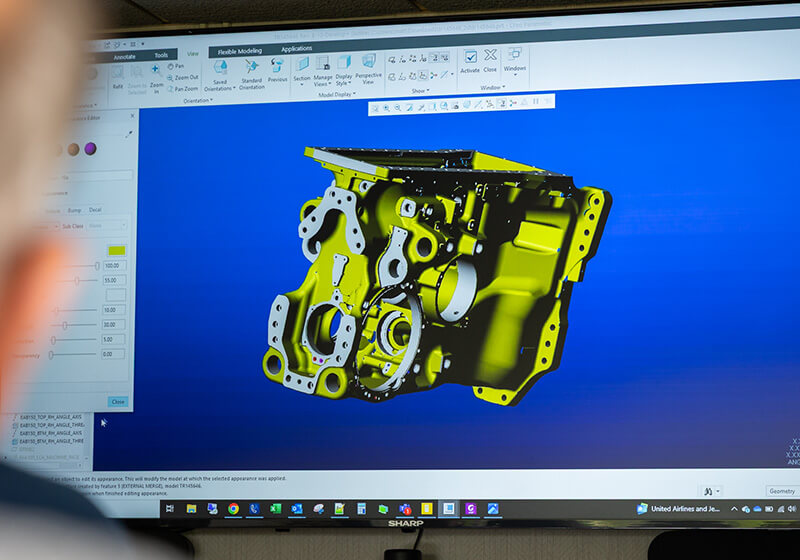

HyPro delivers precision CNC machining powered by more than 220 active machining centers across multiple U.S. facilities. Our expertise covers CNC milling, turning, grinding, drilling and custom tooling with real-time production tracking through our centralized Infor LN ERP system. Services include:

- CNC Milling: 3-, 4-, and 5-axis centers with pallet sizes from 400–1250mm for large, high-mix parts

- CNC Turning: 80+ lathes with 8"–48" chucks for shafts, flanges, and components up to 3,000 lbs

- Grinding: OD/ID and surface grinding for precision tolerances and smooth finishes

- Drilling: Multi-axis, deep-hole, and angled drilling integrated across all machines

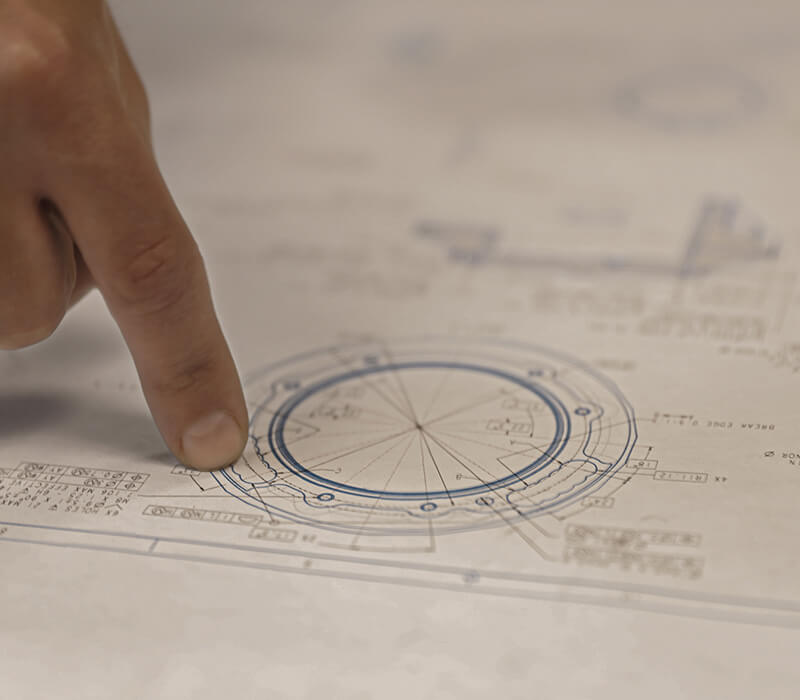

- Custom Tooling: In-house fixture and tool design for faster, consistent production