Steel Parts Manufacturer

Steel remains one of the most widely used engineering materials due to its strength, durability, machinability and versatility. From low-carbon steels used in structural applications to high-strength alloy steels and corrosion-resistant stainless steels, steel offers a broad spectrum of performance characteristics for parts under mechanical, thermal or corrosive stress.

HyPro machines steel parts for demanding applications across power systems, drivetrains and structural platforms. Common part types include:

As an experienced steel parts manufacturer, we customize each steel machining program to meet critical dimensional and performance requirements across small to high-volume production.

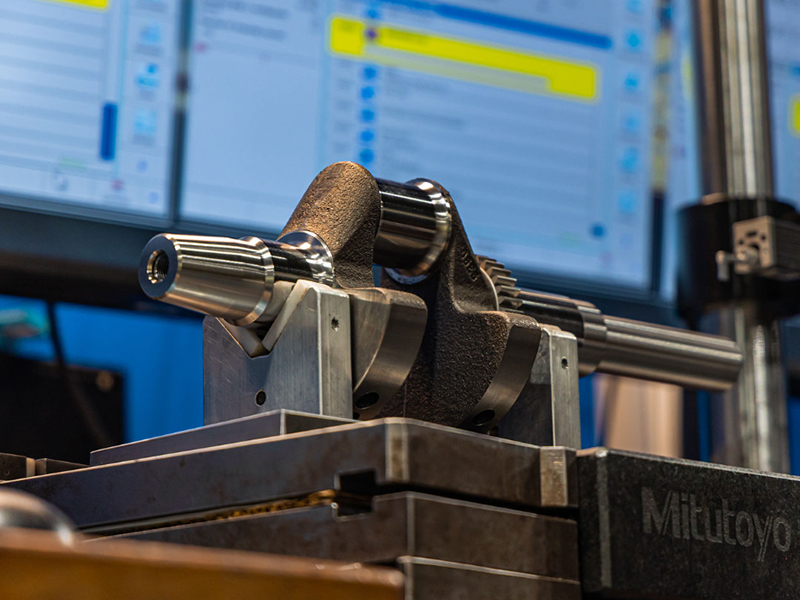

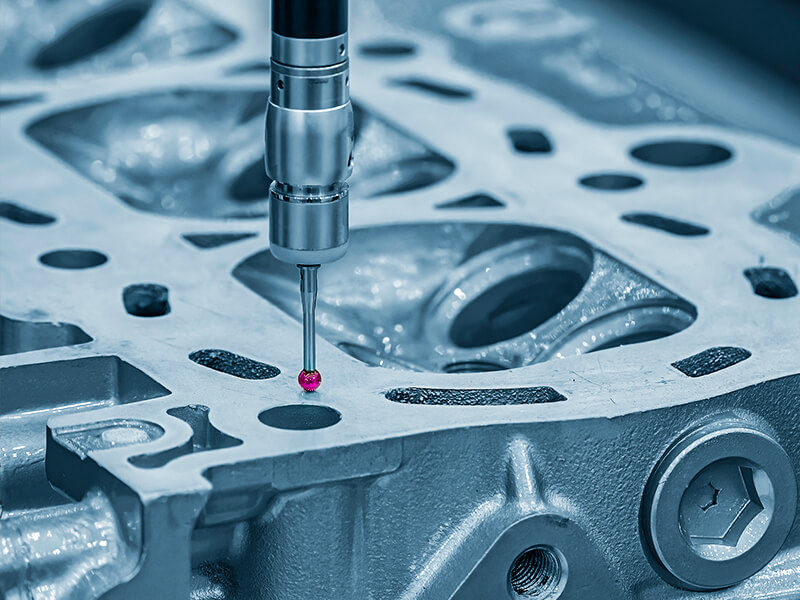

HyPro’s machining capabilities support cast, forged and bar steel inputs with part sizes ranging from under 1 pound up to 9,000 pounds. We use automated cells and manual CNC machines with production-intent fixturing and validated setups to support tight tolerances and repeatability. For long-term supply partnerships, our contract manufacturing programs streamline every stage from design for manufacturability to final inspection.

Our nationwide manufacturing footprint includes specialized facilities:

Every HyPro facility maintains ISO 9001:2015 registration. Our quality systems include:

Whether you're looking for a reliable partner for complex castings or a fully integrated contract manufacturer, HyPro delivers unmatched process depth and manufacturing expertise. Contact our team today to learn how we can support your next machining, assembly or sourcing project.