Aluminum Parts Manufacturer

Aluminum is a preferred material for many applications due to its high strength-to-weight ratio, excellent corrosion resistance and thermal conductivity. It is easily machinable, making it ideal for complex geometries and high-speed production. Aluminum also allows for secondary processes such as anodizing, powder coating and chromating, enhancing both function and aesthetics.

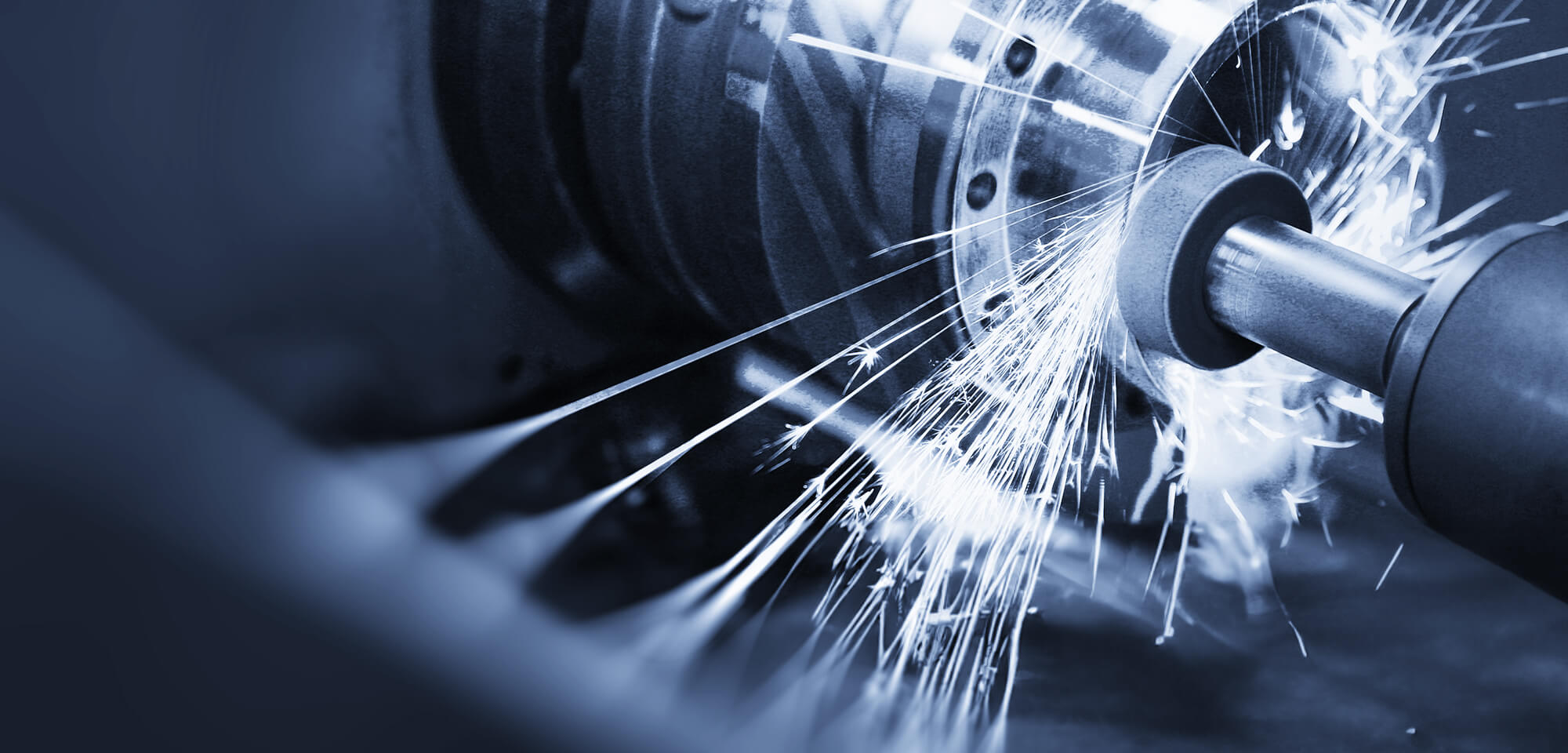

Our aluminum machining programs leverage advanced equipment, including high-speed spindles, rigid fixturing and Fanuc-based automation cells. HyPro’s approach delivers efficiency, accuracy and repeatable quality across medium- to large-volume runs. We support contract manufacturing programs with expertise from design input to final inspection.

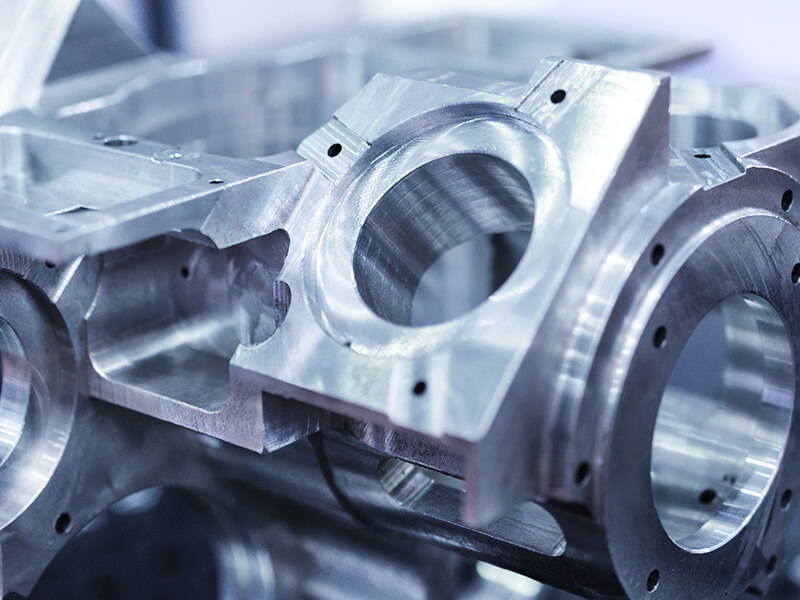

HyPro machines aluminum components for demanding applications in lightweight, corrosive or high-performance environments. Common part types include:

As an experienced aluminum parts manufacturer, we tailor every aluminum machining process to match performance expectations and part-specific tolerances.

Our nationwide manufacturing footprint includes specialized facilities:

Every HyPro facility maintains ISO 9001:2015 registration. Our quality systems include:

Whether you're looking for a reliable partner for complex castings or a fully integrated contract manufacturer, HyPro delivers unmatched process depth and manufacturing expertise. Contact our team today to learn how we can support your next machining, assembly or sourcing project.