Gray Iron Parts Manufacturer

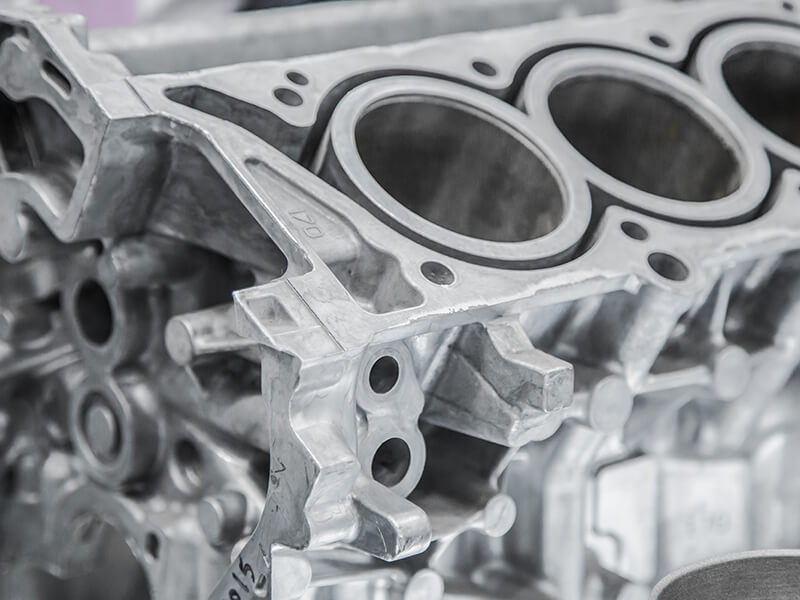

Gray iron, or gray cast iron, is the most commonly used type of cast iron due to its excellent vibration damping, thermal conductivity and castability. Its name comes from the gray appearance of its fracture surface, caused by the graphite flakes in its microstructure. Graphite flakes make gray iron easy to machine and ideal for components requiring dimensional stability and high wear resistance without extreme tensile loads.

HyPro machines gray iron components for applications requiring dimensional stability and high wear resistance without extreme tensile loads. Common part types include:

We work with customers across industries to machine iron parts to meet demanding performance and dimensional requirements.

Our nationwide manufacturing footprint includes specialized facilities:

Every HyPro facility maintains ISO 9001:2015 registration. Our quality systems include:

Whether you're looking for a reliable partner for complex castings or a fully integrated contract manufacturer, HyPro delivers unmatched process depth and manufacturing expertise. Contact our team today to learn how we can support your next machining, assembly or sourcing project.